Ok this might be a really stupid question... the kind that come to you when looking at guitars too much instead of playing them

Neck through guitars with a trem cavity, AKA huge hole clean-through, doesn't that make them weaker than bolt-ons? It's more like hole-through-the-neck than neck-through-guitar.

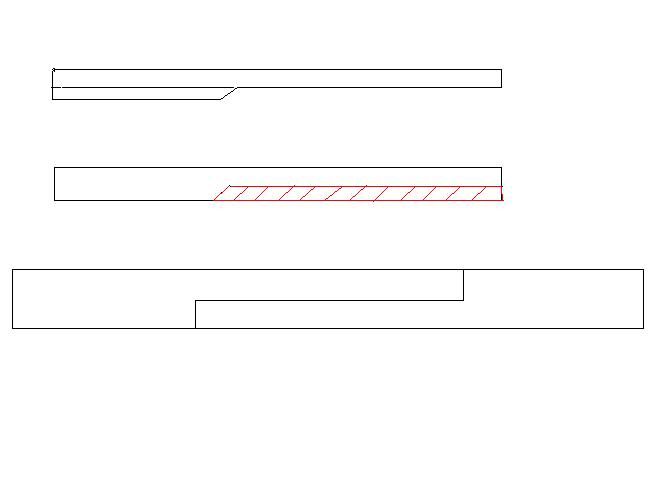

Especially the way Jackson makes them, where the neck piece is only the top half of the guitar's body thickness, you get a neck pickup and that means that on the finished instrument neck wood ends along with the fretboard anyway, trem or no trem.

Am i missing something here?

Neck through guitars with a trem cavity, AKA huge hole clean-through, doesn't that make them weaker than bolt-ons? It's more like hole-through-the-neck than neck-through-guitar.

Especially the way Jackson makes them, where the neck piece is only the top half of the guitar's body thickness, you get a neck pickup and that means that on the finished instrument neck wood ends along with the fretboard anyway, trem or no trem.

Am i missing something here?

Comment