I haven't been on here long but thought I would start a thread on the Kahler 2500s that came on 86 Model 2 & Model 3.

(Can also be found on 80s Fender & Peavey)

http://www.kahlerparts.com/X_pages/X_2500.htm

These were a budget trem & have many weak points. Here are some fixes that have worked for me.

Weak Points

Fine tuners deformed

Soft base plate & block material

Weak saddles/seized rollers

Easily stripped trem bar Threads

Studs

Non locking

Fine tuners.

They are bad about deforming. Don't crank down hard on them.

If they become deformed they can be fixed.

Heat them up wile still mounted & with the thumb screws removed. I use a heavy duty (Weller type) solder gun & push them back into shape. This heating can cause them to become more soft so after they cool, remove them, reheat them & quench in oil. This works well & will last if you don't crank down on them.

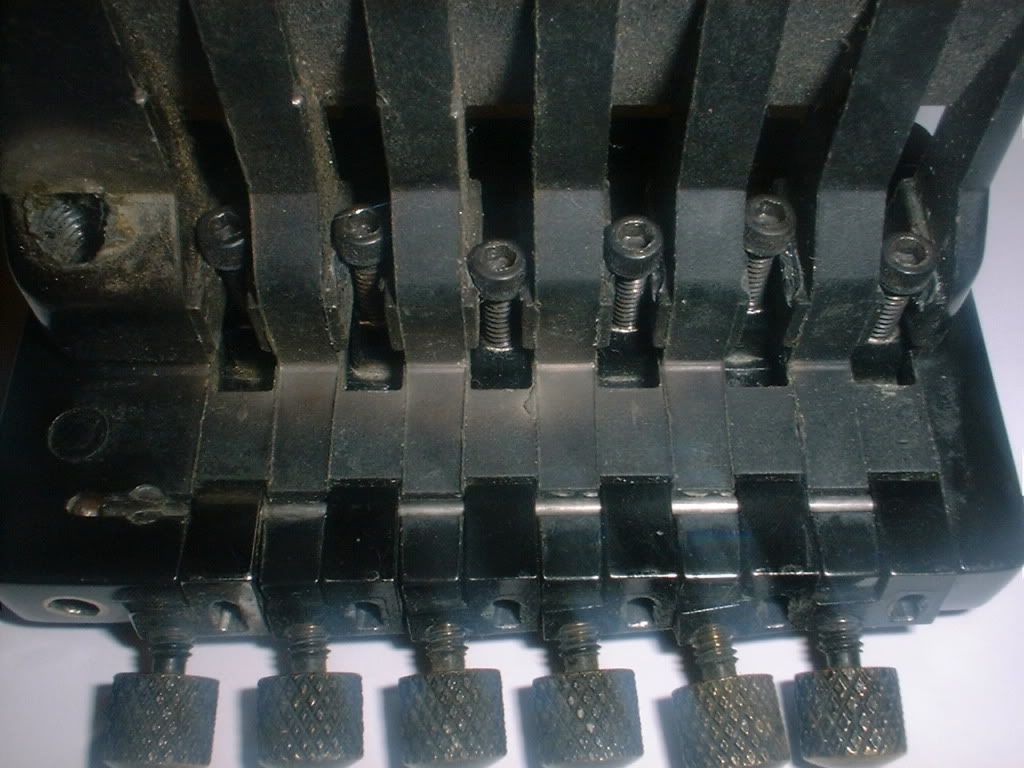

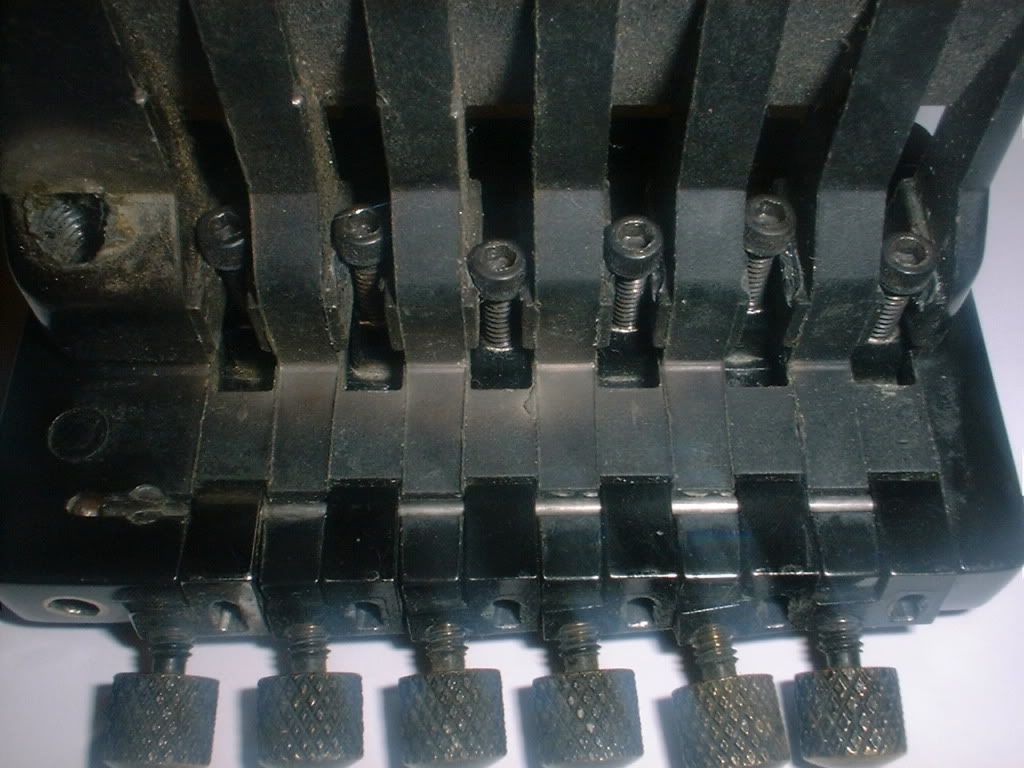

Soft base plates & blocks.

Not much getting around this. It is what it is.

The base plates are bad about wearing where the saddle screws tighten down on the under side. The saddle screws don't need to be heavily torqued down. If you tighten them too hard you can break the saddle. Once the base plate is worn & gouged, setting intonation is a pain.

You can pull the saddles off & file the base area smooth where the screws tighten down. If the base is really badley worn, you can apply J B Weld &

file when it dries.

Saddles

As mentioned above, don't crank down on the saddle screws. The saddles are made of weak alloy & will snap off.

Also keep them clean & oiled. If the rollers seize, soaking the saddle in WD 40 & working the rollers back & forth will usually free them up.

Trem bar threads

Since the block material is weak alloy, The threads are bad about stripping. Or at least wearing, causing bar wobble. If just bar wobble, due to worn threads, Teflon tape on the bar will help.

If stripped, You can re-tap for larger Floyd threaded bars.

Helicoil is much better. If you can find the correct size/pitch kit.

Studs

The studs have the knife edge, and is really a good idea. If the knife edge gets worn, just get new studs. They come in 2 different sizes, so make sure to get the correct size.

http://www.kahlerparts.com/Part_Pages/9496.htm

http://www.kahlerparts.com/Part_Pages/9486.htm

The main problem with the studs is that many have Phillips heads that are easy to strip.

If you need to adjust string hight, Loosen the strings, remove the 2 outer springs from the bridge block and apply a mix of Graphite & petroliun jelly on the stud knife edge. This will relieve the pressure from the bridge on the stud, lubricate, and allow the stud to turn easily.

Also make sure you use an appropriate sized screwdriver.

I have seen these with the Phillips heads stripped, and then someone took pliers to the stud ruining the knife edge.

Non-locking

If properly maintained & setup, these can work pretty well. Not designed for heavy trem use. But for moderate use, they can keep good tuning.

Keep clean. Wipe down after a sweaty shred session.

Keep the trem lubed. I use a tiny bit of 3in1 oil on the saddle rollers & fine tuner threads. Don't drown them in oil. it will attract dirt.

Apply Graphite mixture on bridge Fulcrum points, and in nut slots.

Setup the trem to set level.

Use 4 springs. Four springs will make the trem more stable.

Use good strings.

The string lock that came with the 2500 should have a slick glossy appearance and is made by Kahler. These have good string blocks & hold up better than the latter, licensed (hammered look) string locks.

(Graphite/petroliun jelly) This is what I use. Only a very tiny amount of Petroleum Jelly is needed. You don't want to attract dirt. Just enough to get the Graphite to stick. There are products made specifically for this purpose.

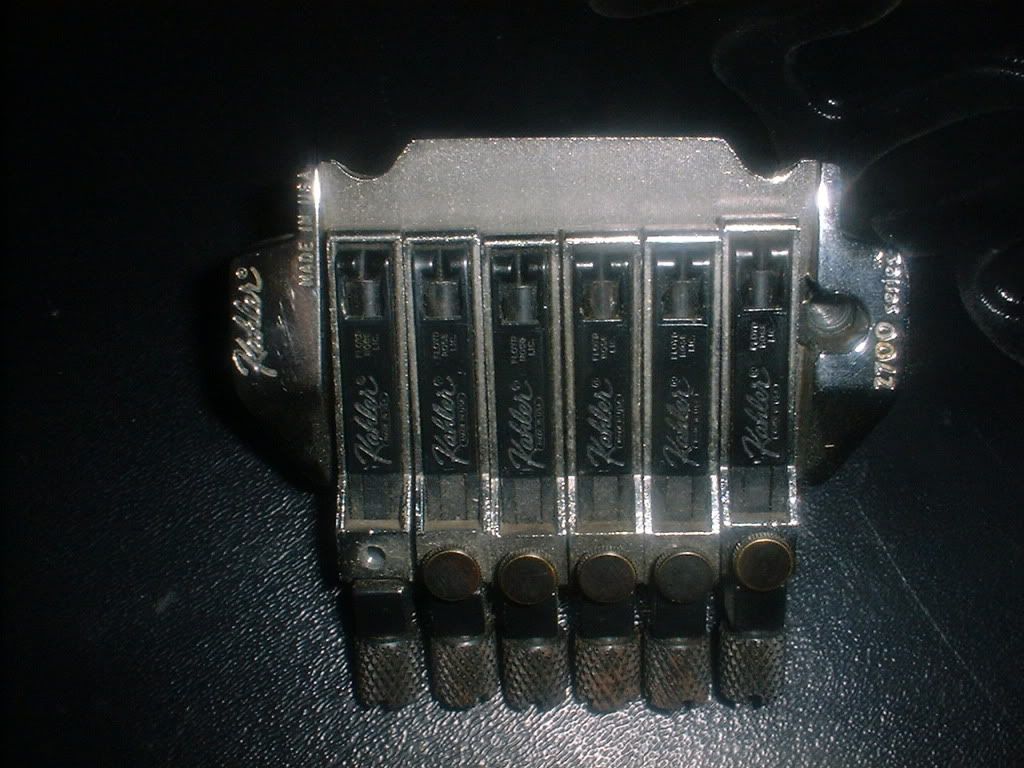

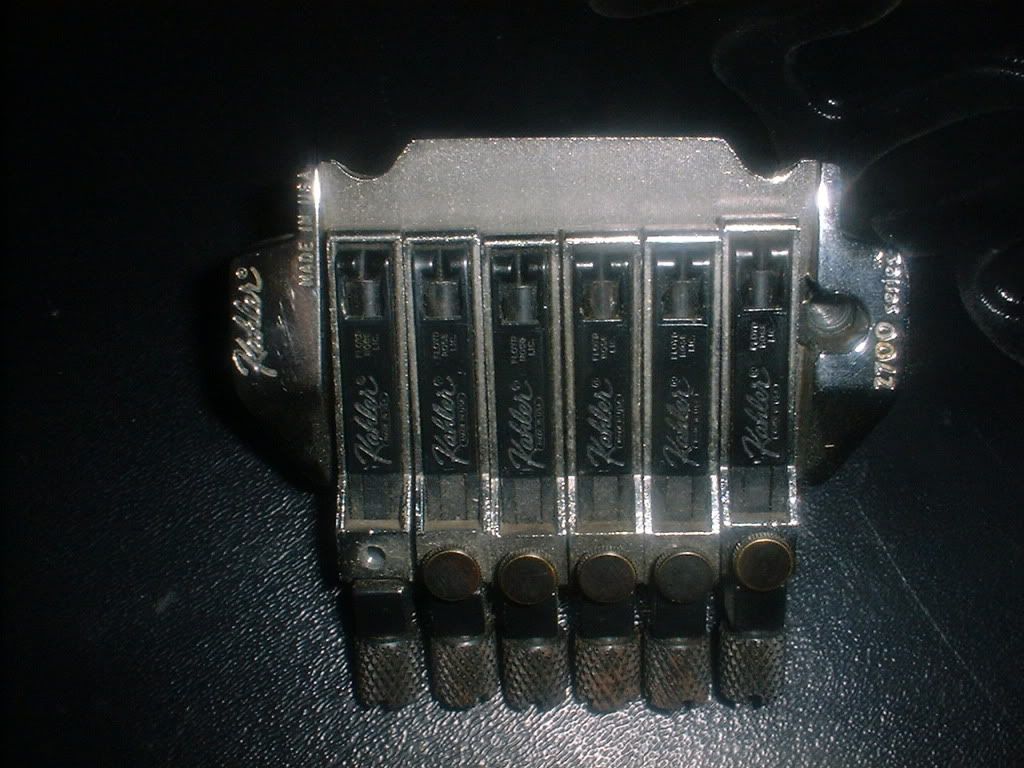

2710

If you are into heavy dives & pullbacks, I suggest upgrading to a Kahler 2710. It has the same stud spacing, is a direct replacement for the 2500 & doesn't require any mods.

Details:

Double locking

High mass

Made of hardened steel

Has excellent fine tuners

Individual string height adjustment

Adjustable string spacing

Replaceable, hardened trem bar module

Tool-less string change

Works with Auto-Latch - http://www.kahlerparts.com/X_pages/X_Auto_Latch.htm

http://www.kahlerparts.com/Part_Pages/T_2710.htm

http://www.kahlerparts.com/Other_Pag...for_Guitar.htm

Hope this is helpful.

If anyone has anything to add, please do so.

(Can also be found on 80s Fender & Peavey)

http://www.kahlerparts.com/X_pages/X_2500.htm

These were a budget trem & have many weak points. Here are some fixes that have worked for me.

Weak Points

Fine tuners deformed

Soft base plate & block material

Weak saddles/seized rollers

Easily stripped trem bar Threads

Studs

Non locking

Fine tuners.

They are bad about deforming. Don't crank down hard on them.

If they become deformed they can be fixed.

Heat them up wile still mounted & with the thumb screws removed. I use a heavy duty (Weller type) solder gun & push them back into shape. This heating can cause them to become more soft so after they cool, remove them, reheat them & quench in oil. This works well & will last if you don't crank down on them.

Soft base plates & blocks.

Not much getting around this. It is what it is.

The base plates are bad about wearing where the saddle screws tighten down on the under side. The saddle screws don't need to be heavily torqued down. If you tighten them too hard you can break the saddle. Once the base plate is worn & gouged, setting intonation is a pain.

You can pull the saddles off & file the base area smooth where the screws tighten down. If the base is really badley worn, you can apply J B Weld &

file when it dries.

Saddles

As mentioned above, don't crank down on the saddle screws. The saddles are made of weak alloy & will snap off.

Also keep them clean & oiled. If the rollers seize, soaking the saddle in WD 40 & working the rollers back & forth will usually free them up.

Trem bar threads

Since the block material is weak alloy, The threads are bad about stripping. Or at least wearing, causing bar wobble. If just bar wobble, due to worn threads, Teflon tape on the bar will help.

If stripped, You can re-tap for larger Floyd threaded bars.

Helicoil is much better. If you can find the correct size/pitch kit.

Studs

The studs have the knife edge, and is really a good idea. If the knife edge gets worn, just get new studs. They come in 2 different sizes, so make sure to get the correct size.

http://www.kahlerparts.com/Part_Pages/9496.htm

http://www.kahlerparts.com/Part_Pages/9486.htm

The main problem with the studs is that many have Phillips heads that are easy to strip.

If you need to adjust string hight, Loosen the strings, remove the 2 outer springs from the bridge block and apply a mix of Graphite & petroliun jelly on the stud knife edge. This will relieve the pressure from the bridge on the stud, lubricate, and allow the stud to turn easily.

Also make sure you use an appropriate sized screwdriver.

I have seen these with the Phillips heads stripped, and then someone took pliers to the stud ruining the knife edge.

Non-locking

If properly maintained & setup, these can work pretty well. Not designed for heavy trem use. But for moderate use, they can keep good tuning.

Keep clean. Wipe down after a sweaty shred session.

Keep the trem lubed. I use a tiny bit of 3in1 oil on the saddle rollers & fine tuner threads. Don't drown them in oil. it will attract dirt.

Apply Graphite mixture on bridge Fulcrum points, and in nut slots.

Setup the trem to set level.

Use 4 springs. Four springs will make the trem more stable.

Use good strings.

The string lock that came with the 2500 should have a slick glossy appearance and is made by Kahler. These have good string blocks & hold up better than the latter, licensed (hammered look) string locks.

(Graphite/petroliun jelly) This is what I use. Only a very tiny amount of Petroleum Jelly is needed. You don't want to attract dirt. Just enough to get the Graphite to stick. There are products made specifically for this purpose.

2710

If you are into heavy dives & pullbacks, I suggest upgrading to a Kahler 2710. It has the same stud spacing, is a direct replacement for the 2500 & doesn't require any mods.

Details:

Double locking

High mass

Made of hardened steel

Has excellent fine tuners

Individual string height adjustment

Adjustable string spacing

Replaceable, hardened trem bar module

Tool-less string change

Works with Auto-Latch - http://www.kahlerparts.com/X_pages/X_Auto_Latch.htm

http://www.kahlerparts.com/Part_Pages/T_2710.htm

http://www.kahlerparts.com/Other_Pag...for_Guitar.htm

Hope this is helpful.

If anyone has anything to add, please do so.

Comment